AVGAS AND ENGINES: LYCOMING’S APPROACH

How are the engine manufacturers preparing for the eventual transition to an unleaded avgas? AOPA posed some questions to Lycoming Engines about the company’s approach to the challenge.

How are the engine manufacturers preparing for the eventual transition to an unleaded avgas? AOPA posed some questions to Lycoming Engines about the company’s approach to the challenge.AOPA: What is your primary focus in considering a transition to unleaded avgas?

Lycoming: Flight safety is Lycoming’s top consideration and is at the forefront of our call for a 100 octane replacement fuel. Flying an aircraft is an inherently complex and demanding activity. An airplane works because it is designed as a system which involves (a) the fuel, (b) the engine, (c) the propeller, (d) the aircraft, (e) the pilot, and (f) the mechanic. A malfunction in any one of these elements can affect flight safety.

Few flight safety inputs are more important than the fuel that allows engines to create and maintain the power needed by the aircraft for predictable flight performance. Without a 100 octane replacement fuel, many legacy and current production aircraft will be unable to operate in the same entire flight envelope for which they were designed. This impact to the aircraft performance window is why—in Lycoming’s viewpoint—the aviation fuels issues are directly related to flight safety.

AOPA: How are you organizing internally to respond to the eventual transition to unleaded avgas?

Lycoming: We are engaged on this subject at several levels. In general, we have been anticipating a change for some time, thus have tried to remain as flexible as possible with our fuel approvals, as evident in our Service Instruction 1070Q. Here are three key categories of effort.

- First, we're working to build out our understanding of the relationship between our engines and unleaded fuels based on almost 20 years of data. Many Lycoming engine models have been approved to run on unleaded aviation grade fuels since 1995. This was made possible by the materials and component designs used in our engines combined with more than two decades of service history—and that data history is part of our baseline for taking steps for a next generation avgas.

- Second, we have a public component to our strategy. We have provided the FAA with engines and component parts, as well as engineering support, to assist with the evaluation of potential future, unleaded, fuels; and we have moved Lycoming to a much more public stance via our ongoing fuels education campaign and our commitment to unbiased, independent fuels research.

- Third, we are introducing new engine technology. In addition to their many other advanced features, the iE2 integrated electronic engine, now flying in the Lancair Evolution, and 233 series light sport aircraft engine are both capable of operating on lower octane unleaded fuels.

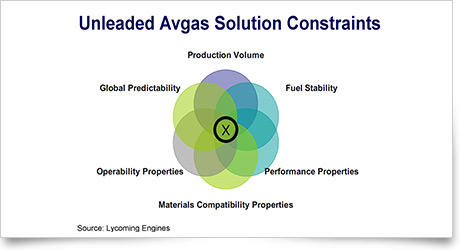

AOPA: From an engine manufacturer’s perspective, what do you see as the greatest technical challenge in a single-fuel solution for a future unleaded avgas?

Lycoming: There are a number of challenges that will need to be addressed, and focusing on the technical aspects is only one dimension of the problem. So let’s assume—and it is a big assumption—that the market demand has been established for a 100LL equivalent and that the necessary capital investment has flowed to the innovators to make their processes economical. It has now been demonstrated that you can get to “100LL performance” without TEL (tetraethyl lead) via multiple paths.

The greatest technical challenge appears to be mitigating potential materials compatibility issues on legacy aircraft.

While this may seem to be a daunting challenge on the surface, one of the most rapidly advancing fields in engineering has been in the materials science area. Lycoming believes that there is a high probability that any materials compatibility challenges could be resolved within the natural maintenance life cycle of equipment. It is also the reason why we point out that we need to identify a solution in the next one to two years in order to be able to have 10 years for a roll-out without major economic impact.